Our Infrastructure

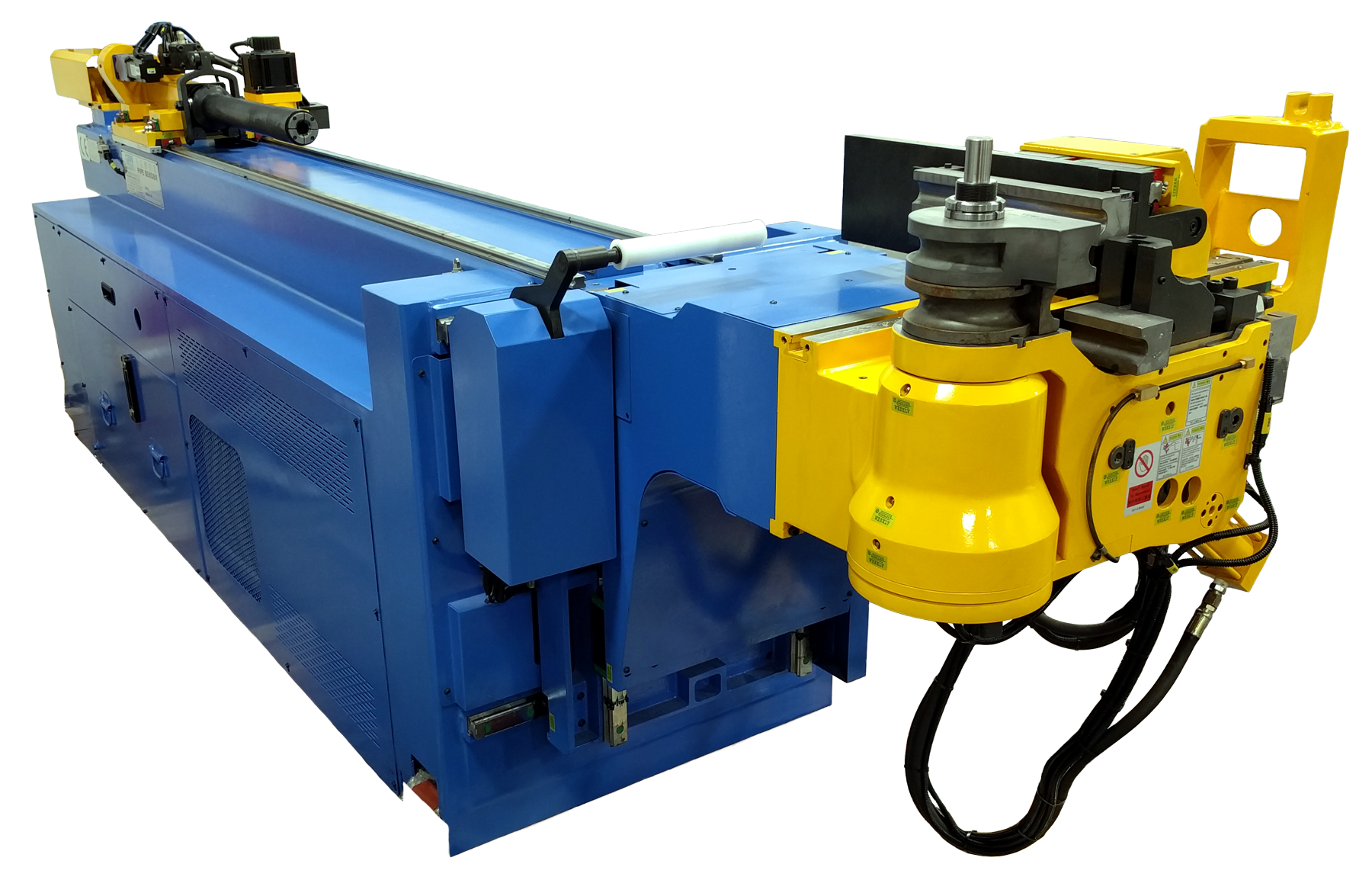

CNC hydraulic Tube Bending Machine

Automatic bender type TDR is intended for 3D tube bending using 2 separate bending tool stacks in one working cycle. The bending arm (C axis) is controlled by a hydraulic drive as well as the clamping elements, and the vertical / horizontal movement of the bend head is controlled by two hydraulic cylinders. Y & B axis are controlled electrically (tube rotation and support shift). This machine also comes equipped with automatic mandrel retraction and lubrication system.

FRONIUS TRANSSTEEL 5000 PULSE

ROBOTIC WELDING – TAST / Touch Sensing / Multi pass and Root pass Memorization

This new generation of Arc Welding robots stands out based on its productivity advancements and rapid integration times. To utilize space more efficiently, the new ARC Mate 100iD has received a more sophisticated, curved design, which allows it to effortlessly operate in compact welding cells. It features a fully integrated welding hosepack and utility cables, which further economizes the workspace.

A larger workspace, reach and stroke, even in the backflip area, allows for a bigger working range. Improved rigidity and repeatability together with faster motion speed, mean increased productivity.

A larger workspace, reach and stroke, even in the backflip area, allows for a bigger working range. Improved rigidity and repeatability together with faster motion speed, mean increased productivity.

DOUBLE COLUMN MACHINE

Adapting to the structural characteristics of traditional gantry products with strong rigidity and wide processing range, integrating advanced technical elements and pursuing the development concept of high efficiency, high precision, energy saving and amenity. Widely used in mold, aviation, rail transit, automobile, household appliances, medical and other high-end manufacturing industries.

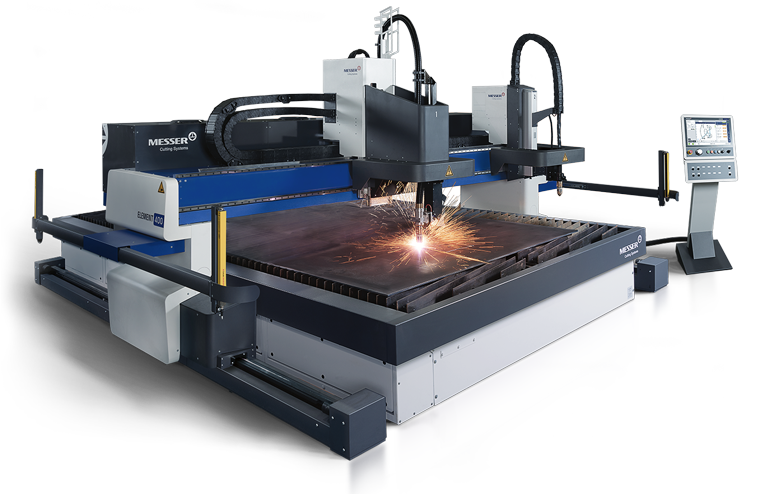

CNC Oxy fuel Flame Cutting

CNC Vertical milling center

CNC Turning centers

CNC Tube bending

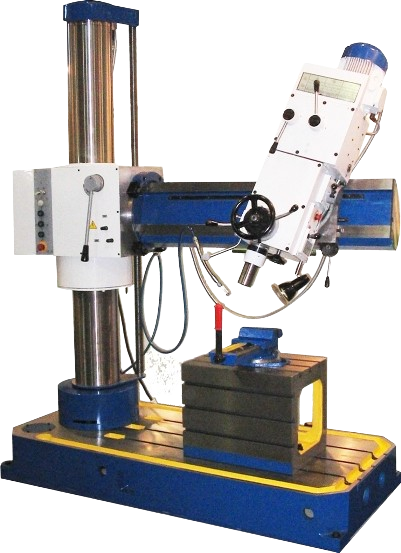

Radial Drilling STANKO 2" Conventional